Installation

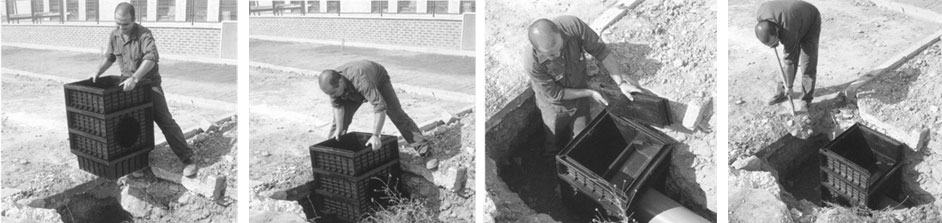

Please download the “Installation recommendations for the access chambers”: In addition to its design benefits (high strength, versatility, quality finish), its quick and easy installation make the HIDROSTANK access chamber an effective alternative to traditional solutions. On the one hand, the lightness of the Hidrostank access chamber facilitates transportboth from the factory to the civil work and and inside it. Furthermore, manual handling, without heavy machinery (crane, truck …) dramatically speed installation up. The modularity of the access chamber allows easy assembling of the Hidrostank chamber to the required dimensions for each project. You can achieve desired height very easily with additional modules. The system also allows to make the inlets in situ, without being conditioned by any premarked window(as in concrete chambers). This way guarantees a quality finish, and avoids to do any additional plastering to receive the pipes properly as it happens in traditional systems. This quick and easy installation, without cranes, truck …reduce both execution time and labor required. This saves in time, labor and machinery make the Hidrostank access chamber a very profitable alternative to traditional concrete chambers and minimizes the risk of accidents that manipulation of concrete and brick manholes may cause.

|

|